Rice, Corn, & Barley Harvest

Something new (new for me, at least)! You can subscribe to my posts and get notified each time there’s a new one. See “SUBSCRIBE BY EMAIL,” to the right.

—————————————–

It’s been awhile since the grains have been harvested so it’s time to prepare them for consumption. Longest in preparation will be barley.

It’s been awhile since the grains have been harvested so it’s time to prepare them for consumption. Longest in preparation will be barley.

The barley is from last year’s harvest, and the grain-laden stalks have been bundled together and hanging from a kitchen rafter since then. I’ve procrastinated processing because of last year’s frustrations in trying to thresh wheat, also grown last year; the grains clung tenaciously to their stalks and no amount of battering would thoroughly separate them. I’ve also procrastinated because the bundle of barley’s tawny brown stems, with long, delicate, spiky awns emerging from the heads, look so decorative dangling upside down near the kitchen ceiling.

A bare spot now remains where the barley once hung. Earlier today, after being stuffed into a pillowcase and batted against a brick wall, the stalks easily released their plump grains. I separated the grain rom the chaff by pouring the grains back and forth between two buckets in a slight breeze, and soon had the whole crop cleaned.

As you’ve probably guessed by now, my barley crop wasn’t measured in tons or even bushels. I had planted a 3 foot by 3 foot area and reaped a quarter of a pound. Consulting my 1914 “Farmer’s Cyclopedia of Agriculture,” an acre of barley (back then and in Iowa) averaged 45 bushels of barley, or 1,800 pounds, which would translate to a bit over one-third of a pound for my 9 square foot plot. Respectable for my first try.

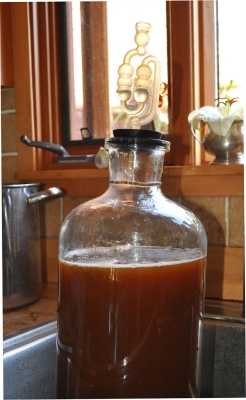

The end-product for my crop will be beer. More specifically, the goal was to find out how much barley to grow to make a 6-pack. My next step, then, is to malt the barley. More on that at a later date . . .

————————————————–

I “hauled in” the rice harvest back in early October, all 40 grams of it. That 40 grams was not a bad yield considering that I got the seedlings started late; that I only planted a 2 foot by 3 foot bed of it; that it was growing under dryland conditions, which yields less than wetland rice; and the variety I planted, Hayayuki, is a wetland variety. Still, it was fun.

The aforementioned limitations are nothing compared to the limitation in preparing the rice for consumption. Like most other grains, rice has a hull that needs to be removed before the grain can be eaten. (The hull is no impediment with barley for malting because what’s used for beer is maltose-laden water that is leached through the sprouted, cracked grain.) Hullers are available for small-scale grain processing, but are neither economical nor capable of handling nano-yields such as my 40 grams.

A conversation with Ben Falk (www.wholesystemsdesign.com), who had given me the seeds and has harvested over 100 pounds of rice in Vermont, did not leave me optimistic about getting off those hulls. (He has a small huller.) No need for me to try cracking them off with a rolling pin, boiling them and hoping they would float up to be skimmed off, or toasting — he’d already tried all that.

Years ago, I got a Solis coffee grinder that does an adjustable grind. How about setting the Solis to barely grind the rice, just enough to crack off the hulls? The problem is that the largest setting was a bit too small for the rice grains. Still, no other options presented themselves. What I now have is cracked rice. I cooked some; the flavor was very bland, even for rice.

————————————————-

It isn’t only a lot more growing experience that is responsible for my much more successful crop of a third grain: corn. Corn is easier to grow, to harvest, and to process than other grains on a home garden scale. I grow popcorn and polenta corn in addition to, of course, sweet corn, the latter considered a vegetable because it’s eaten “green,” that is, before full maturity.

It’s with good reason that corn has been such a success for so long here in the Americas. The grains are large, they come packed together in a single ear, and that ear is covered by one easily shucked husk. Corn is such a successful cultivated grain that it can’t even survive in the wild. An ear dropped to the ground would sprout too many seedlings so close together that they would be stunted fighting each other for water, light, and nutrients.

Processing popcorn and polenta corn entails nothing more than picking it, pulling back the husk, and hanging it from kitchen rafters until ready for use. Giving a ear an “indian burn” snaps off kernels for popping or grinding.

————————————————-

One more home-grown grain rounds out my larder. Chestnuts. They’re not actually a grain but are a uniquely starchy nut so fulfill much the same purpose as any grain in the diet. Chestnuts have the advantages of being perennial, borne on an attractive tree, and, because they bloom late and have few pests, bearing reliably.

Chestnut preparation is easy: One cut crosswise about half way through each nut, then roasting in a hot oven for about 30 minutes. Delicious.